Our solutions in tax, compliance, and business consulting to help you achieve financial clarity, streamline operations

Specialized in Reliability, Availability & Maintainability analysis using advanced tools and modeling techniques. Delivered successful projects across globally.

Read MoreDelivering exceptional reliability outcomes across global oil & gas, mining, and infrastructure projects. Partnering with industry leaders to consistently achieve 95-99% operational availability through advanced RAM frameworks.

From SAGD facilities to refineries and phosphate mining plants—we deliver integrated RAM, FMEA, RBI, and lifecycle cost solutions from concept to operations, ensuring data-driven decisions that maximize performance and sustainability.

Read MoreDelivering RAM analysis and asset integrity excellence across North America, Middle East, and Europe.

Oil sands, refining, and upstream operations

Phosphate and energy facilities

Industrial and energy projects

Across multiple regions and industries

Registered Professional Engineer (P.Eng.) in Alberta, Canada with Master's Degree in Petroleum Engineering from University of Alberta. 25+ years hands-on experience in RAM modeling and asset reliability.

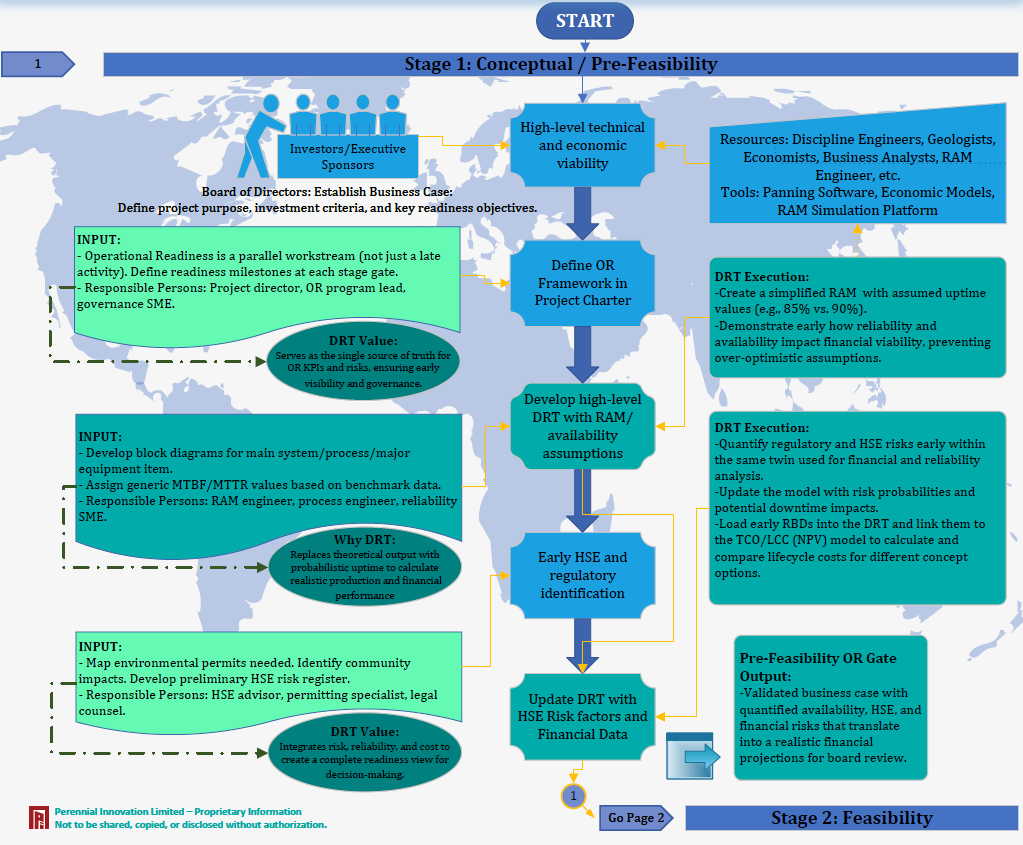

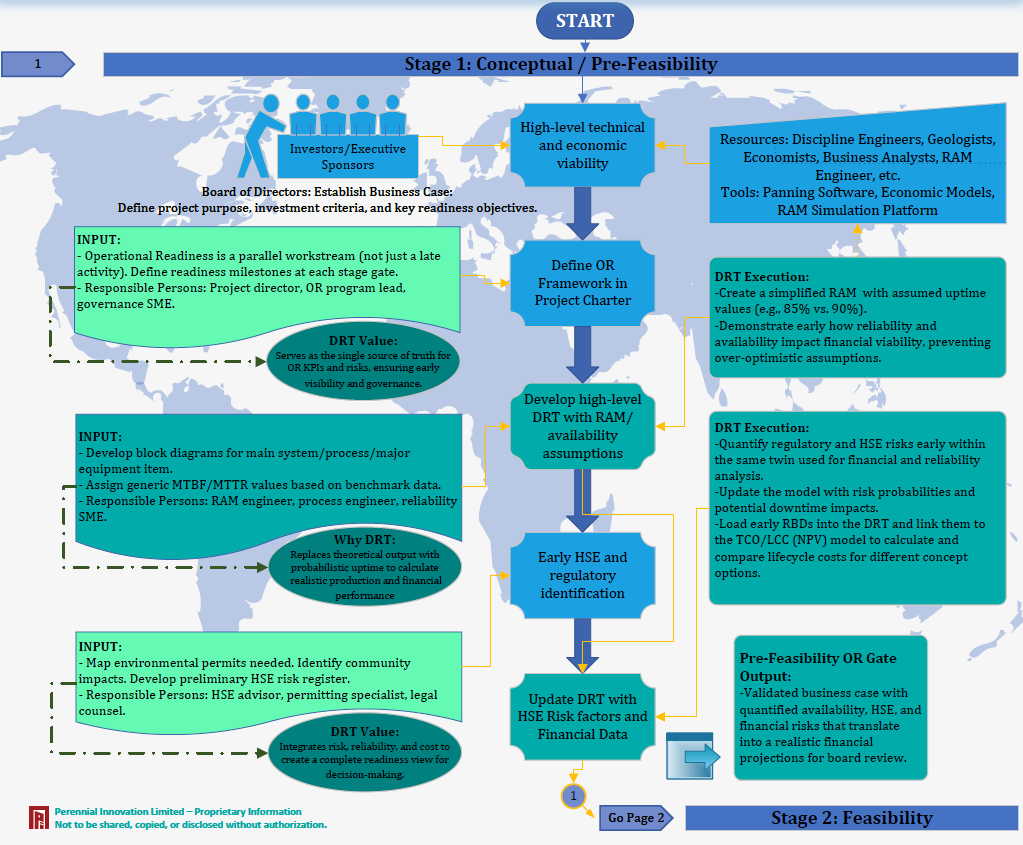

Advanced simulation and modeling tools, Digital Risk Twin (DRT) framework integration, and industry-standard project management and risk-based inspection software.

Support from concept through operations—Feasibility → FEED → Detailed Design → Construction → Commissioning → Operations. Seamless design-to-operations handover.

Quantifiable improvements in operational availability, risk reduction and cost optimization, data-driven decision support and KPI tracking.

Smooth transition from engineering to operations through structured documentation, targeted knowledge transfer, and ongoing technical support, delivering implementation confidence and sustained asset performance.

We use advanced reliability modeling to help you design better facilities, predict equipment performance, and optimize maintenance strategies—saving millions in capital costs while maximizing uptime.

We gather your facility drawings, equipment data, and historical performance information.

We create a digital reliability model showing how your equipment works together.

We test thousands of scenarios to predict performance and identify weak points.

You get clear recommendations on how to improve reliability and reduce costs.

Avoid over-engineering by knowing exactly how much redundancy you need. Past clients saved $3M-$15M in capital costs.

Predict and improve facility availability before you build. We help achieve 95-99%+ operational availability.

Know which equipment matters most. Spend money maintaining critical assets, not everything equally.

Buy the right spares based on actual risk. Clients typically reduce spare parts inventory by 20-30%.

Compare design options with real numbers. Know the reliability impact before spending money.

Identify problems in design phase, not during operations. Prevent costly surprises after startup.

We use industry-leading reliability analysis tools and follow international engineering standards to ensure accurate, defensible results for your projects.

Comprehensive corrosion management, inspection planning, and integrity programs aligned with industry standards (API, ASME, NACE, Saudi Aramco SAEP).

Read MoreSystematic identification of potential failure modes, risk assessment, and mitigation strategies to enhance system reliability and safety.

Read MoreTotal cost of ownership modeling, economic evaluation, and investment decision support for capital projects and asset optimization initiatives.

Read MoreAPI 580/581 compliant risk assessment, inspection planning, and prioritization using advanced RBI software to optimize integrity management programs.

Read More