Our solutions in tax, compliance, and business consulting to help you achieve financial clarity, streamline operations

Transforming design data into operational insight, Perennial's Model-Based RAM (MBRAM) framework empowers smarter engineering and asset management decisions. Our reliability simulations help clients design more resilient facilities, predict equipment performance, and optimize maintenance strategies, reducing unplanned downtime and achieving significant CAPEX and OPEX savings while maximizing uptime.

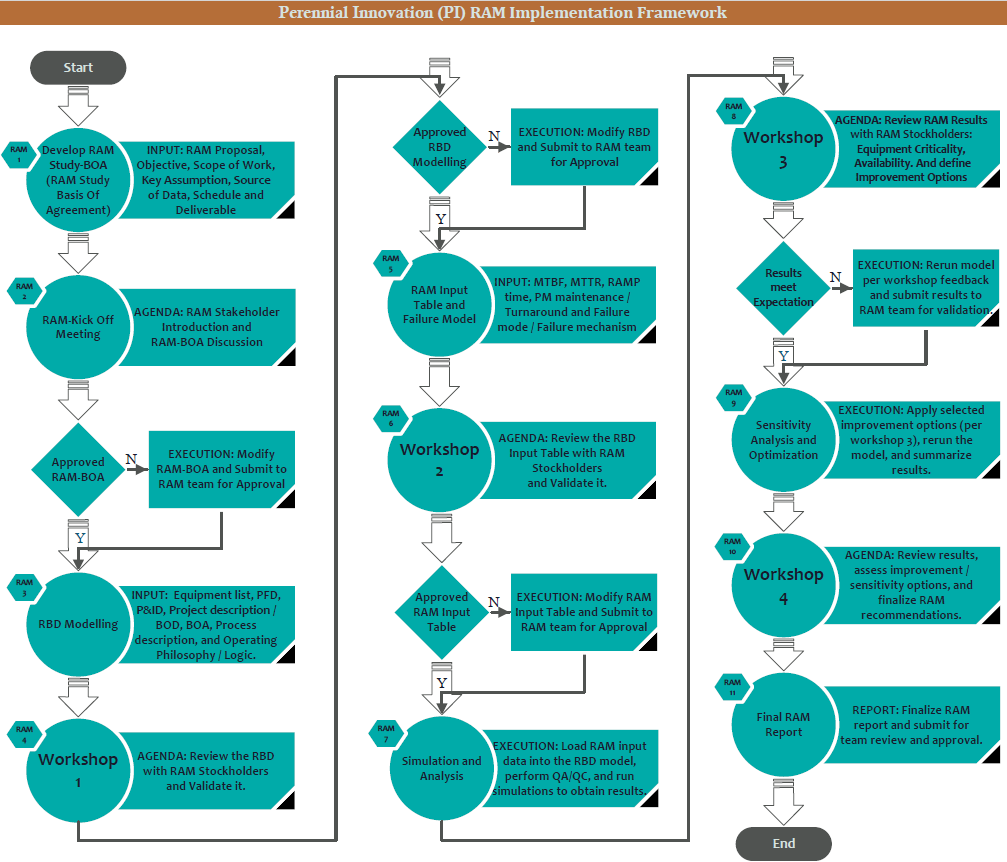

MBRAM™ - Perennial Innovation's Model-Based RAM (Reliability, Availability, Maintainability) delivers a structured, data-driven approach to achieving world-class reliability, availability, and maintainability performance.

Built on model-based engineering principles, the framework connects design intent, operational mission profiles, and real-time KPI verification within a single digital system.

It enables organizations to simulate, optimize, and validate system performance before and during operation reducing downtime, enhancing asset reliability, and improving lifecycle economics.

By integrating RAM analysis with Digital Risk Twin (DRT) technology, PI transforms reliability management from a reactive activity into a proactive, predictive discipline that drives sustained operational excellence.

We don't start until we agree on the rules

Ensures the model reflects your operating reality, not generic industry averages.

Translate P&IDs into reliability logic

Review logic with stakeholders to confirm it matches actual design.

Populate with real-world failure data

If a vendor claims a pump never fails, we challenge it.

Run Monte Carlo analysis and identify bottlenecks

We don't email a report—we present findings interactively.

Quantify improvements and finalize roadmap

Finalize the roadmap with management.

Most RAM studies deliver a report. MBRAM delivers a validated, stakeholder-aligned reliability model that evolves with your project.

4 structured workshops ensure every assumption is challenged and validated by your team—not just our analysts.

Monte Carlo simulation with 10,000+ iterations, Weibull analysis, and full system logic modeling—not spreadsheet estimates.

The model doesn't get archived—it becomes your Digital Risk Twin, continuously updated through project phases.

Our RAM Report is structured to provide clear, data-driven insights and actionable recommendations tailored to each client's operational goals.

Every RAM study deliverable is developed in alignment with international standards and customized to support design assurance, operational readiness, and lifecycle optimization.

A concise overview of study objectives, key findings, and availability performance highlights.

Background, project context, and study objectives aligned with client requirements.

A comprehensive list of engineering and design references, nomenclature, terminology definitions, and reliability data sources used in developing the RAM model and analysis.

Definition of reliability and availability targets to be validated through modeling.

System boundaries, included facilities, and equipment coverage.

Input data, methodologies, and reliability data references.

Boundary conditions, maintenance philosophy, failure data sources, and modeling constraints etc.

Description of data integration and reliability modeling workflow and methodology.

Visual representation of system logic and redundancy configuration.

Detailed approach to failure mode definition, repair modeling, and failure distribution.

Analysis of system availability, equipment criticality, and production loss contributors etc.

Practical actions for improving reliability, optimizing maintenance, and achieving availability targets, etc.

Supporting data, sensitivity analyses, or additional modeling outputs, etc.

Every RAM Report from Perennial Innovation Limited is designed not just to demonstrate system performance, but to enable decision-making, helping project teams and operators identify reliability bottlenecks, justify design changes, and build a clear roadmap toward targeted operational availability.