Our solutions in tax, compliance, and business consulting to help you achieve financial clarity, streamline operations

Reliability analysis for large-scale desalination facility water supply infrastructure serving sustainable development zone spanning 26,500 km²

Critical infrastructure component supporting one of the world's largest integrated sustainable development programs

This Water Intake Pump Station serves as the primary water supply component for a large-scale seawater desalination and treatment system. Located along the coastal shoreline, the facility draws seawater to the downstream desalination plant, which will ultimately deliver up to 500,000 m³/day of treated water to support a sustainable economic zone incorporating industrial cities, ports, research hubs, tourism facilities, residential, and smart infrastructure—all built around innovation and environmental stewardship.

Systematic probabilistic approach evaluating design alternatives and operational scenarios

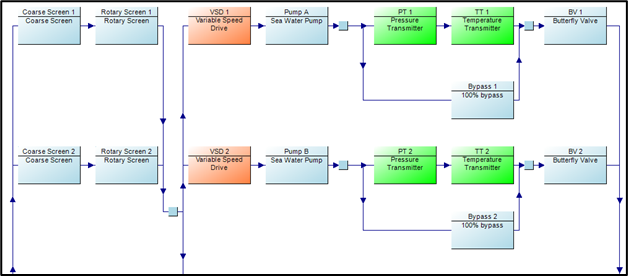

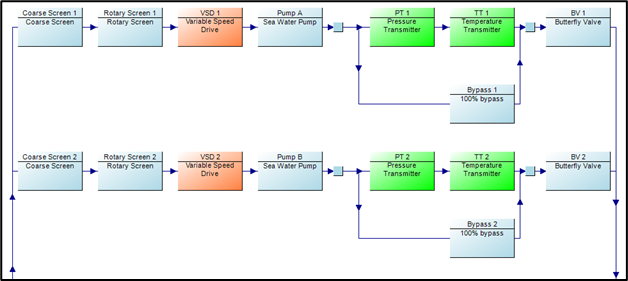

Developed detailed reliability models capturing N+1 and 2N pump configurations with various standby strategies (hot standby, cold standby, load sharing). Models accounted for common cause failures, maintenance unavailability, and demand-based operational profiles to accurately represent system behavior under normal and degraded conditions.

Executed 500+ Monte Carlo iterations simulating pump failures, maintenance events, and repair activities over a 20-year operational horizon. The simulation incorporated time-varying demand profiles, seasonal variations, and planned maintenance shutdown windows to capture realistic operational scenarios and quantify availability with statistical confidence.

Characterized pump failure mechanisms using Weibull reliability functions fitted to centrifugal pump operating data from similar marine environments. Key failure modes analyzed included mechanical seal failures, bearing degradation, impeller erosion, and motor failures—each modeled with appropriate failure distributions reflecting wear-out, random, and infant mortality characteristics.

Simulated pump station performance under variable demand conditions ranging from initial "First Water" production (30,000 m³/day) to full design capacity (500,000 m³/day). Models captured load-dependent failure rates, turndown constraints, and pump cycling impacts to ensure operability across the full operational envelope.

Redundant pumping system with hot standby configuration ensuring uninterrupted water supply

Configuration: 4 × 25% Duty Pumps + 2 × 25% Hot Standby

Redundancy Philosophy: N+2 with automatic switchover on failure detection

Capacity: Each pump rated for 250,000 m³/day

Availability Requirement: >99% operational availability

Comprehensive evaluation of alternative configurations balancing reliability, cost, and operational flexibility

Configuration: 4 Pumps are running + 2 Pumps are standby with Double Forebay

Predicted Availability: 99.9%

✓ Meets 99% availability requirement

Configuration: 4 Pumps are running + 2 Pumps are standby with Single Forebay

Predicted Availability: 99.9%

✓ Meets all reliability and operational requirements

✓ Provides operational flexibility for ramp-up phase

99.9% Operational Availability

Design Option B selected - exceeds 99% target with robust operational margin

Comprehensive technical documentation supporting design selection and lifecycle planning

Content: Executive summary, design option comparison, availability predictions with confidence intervals, sensitivity analysis, and operational recommendations

Format: Professional PDF (100-150 pages)

Content: Detailed RBD models for each design option showing redundancy logic, failure propagation paths, and operational states

Format: Technical drawings and simulation model files

Content: Lifecycle cost comparison (CAPEX vs OPEX trade-offs), business case justification for recommended option, and ROI quantification

Format: Excel-based financial model

Content: Preventive maintenance schedules, inspection protocols, condition monitoring recommendations, and spare parts requirements

Format: Maintenance planning database

Content: Start-up sequences, normal operations, pump switchover procedures, and emergency shutdown protocols

Format: Standard Operating Procedures (SOPs)

Content: KPI definitions, data collection requirements, performance thresholds, and continuous improvement framework

Format: Operational readiness dashboard specifications

Validated infrastructure reliability ensures consistent water delivery supporting sustainable development and population growth across the economic zone

Optimized pump configuration reduces energy consumption and environmental footprint while maintaining performance requirements

RAM study integrated with digital twin framework enabling predictive maintenance and real-time performance optimization

Infrastructure supports research facilities, technology development, and industrial innovation across the broader economic zone

RAM analysis improves and validate the reliability of brine-handling and energy-intensive systems, ensuring stable ZLD operation with minimal downtime. This reduces energy losses, enhances efficiency, and directly supports the desalination plant’s sustainability and net-zero goals.

Lifecycle optimization approach supports resource efficiency, waste reduction, and sustainable operational practices

Validated that recommended design configuration achieves 99.9% operational availability exceeding the 99% target with comfortable operational margin.

Data-driven design selection eliminated unnecessary support structure while maintaining reliability, achieving millions in capital cost savings compared to over-engineered alternatives.

Quantitative comparison of design alternatives provided objective basis for investment decisions with clear cost-benefit justification

Selected configuration supports flexible operations during production ramp-up phase (30,000 to 500,000 m³/day) with maintained reliability

Reinforced project positioning as global benchmark for sustainable infrastructure development through optimized, resilient design

Delivered actionable insights supporting both engineering design finalization and lifecycle cost optimization strategies